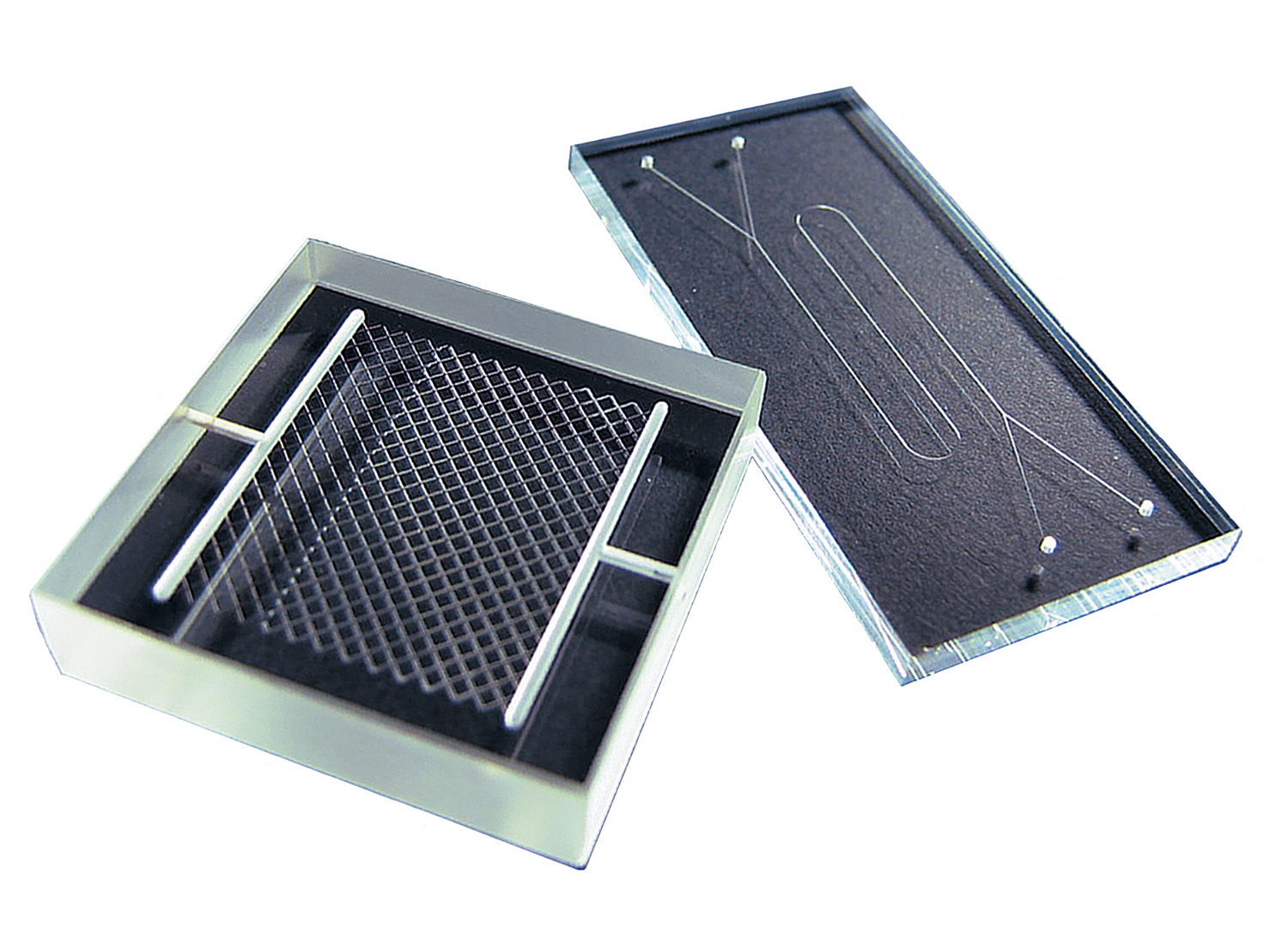

Microfluidic chip is an ultra-precision machined product which formed the minute channel of micron order on the silica glass substrate by applying lithography technology, and is now being used in analyzing minute amounts of sample and in composing microchemistry. We are realizing the high-grade microfluidic chip. Further, we are now engaged in processing the parts for use with MEMS by using our micro-machining technology which is capable of manufacturing the microfluidic chip. It is now available at our company to realize the MEMS products having excellent temperature-stability by using silica glass which has low coefficient of thermal expansion.

Note) MEMS is the abbreviation of Micro Electro Mechanical System, and indicates such small devices as sensors, actuators and etc. with fine electrical elements as well as fine mechanical elements incorporated in a base by applying various fine processing technologies such as semiconductor manufacturing technology, laser manufacturing technology and etc.

| Microfluidic Chip Specifications |

| Item |

Specification |

| Product Size |

≤ □5 inches |

| Channel Width |

≥ 5 µm |

| Channel Depth |

≥ 2 µm |

| Hole Size on Cover Plate |

≥ φ0.3 mm |

| Typical values. Product specifications can be arranged according to proposals. |

Tosoh manufactures various kinds of precision products for semiconductor producing equipment and optical communication-related equipment, by making use of excellent characteristics of silica glass such as good optical transparency, heat resisting properties, anti-solvent characteristics, and high purity, low thermal expansion and the like. And we are building up our products by selecting silica glass materials and choosing the best manufacturing methods based upon customer’s required specifications.

| Variation of Materials and Process |

| Item |

Variation |

| Silica Glass Material |

Transparent, Opaque, Black quartz |

| Machining |

Grooving, Circle hole, Square hole |

| Surface Finish |

Optical polish, Flame polish, Ground |

| Masking |

Cr coating, Al coating, Masking with black quartz |