| Applications: |

Modifier and compatibilizer

H6051K can modify mechanical, recycling, flexible and adhesive properties for polar polymers. It shows excellent performance as a compatibilizer between polyolefins and polar polymers.

Examples of polymers that can be modified

- Ethylene-vinyl alcohol copolymer (EVOH)

- Polyamide (PA6, PA66, etc.)

- Polyesters (PBT, PETG, PET, etc.)

- Polyolefins (PE, EVA, PP, etc.)

Processing aid and lubricant

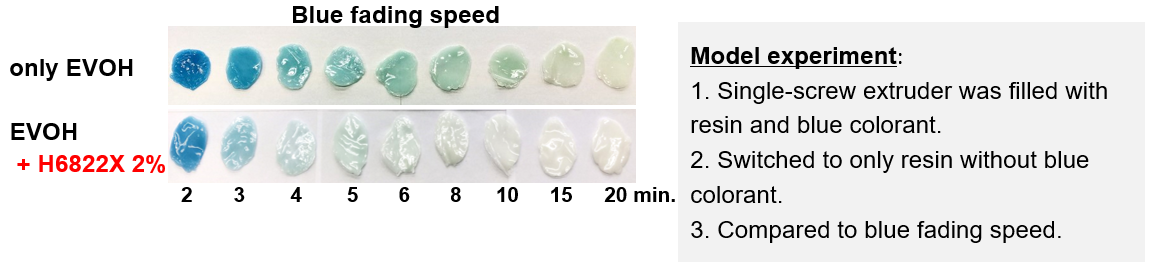

H6822X functions to enhance the flowability of polymers. Polymers with H6822X can prevent long-time residence of the polymer in an extruder (Figure 1). It is expected to reduce contamination such as gel into product, and reduce frequency of thorough cleaning.

Figure 1. Model experimental results of residence time in extruder

Adhesives

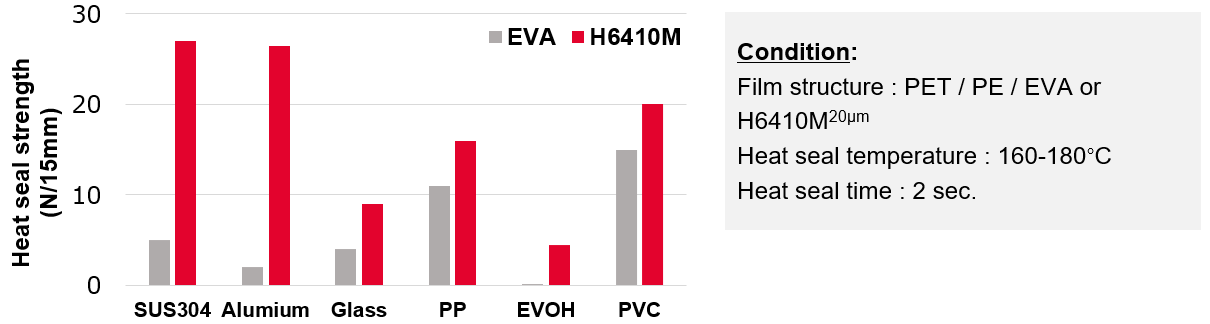

H6410M has good adhesion to metal, polymer, glass, paper, and fabrics (Figure 2). It can be used in general molding and processing machines.

Figure 2. Adhesive performance of Melthene-H to each substrate

|